1. F series connector brief introduction:

The F series micro-circular high-density connector is a split-type push-pull structure. It has a self-locking function after plugging, and a semi-circular positioning piece is used inside to prevent errors. The positioning piece multi-party positioning system prevents the wrong insertion and removal on the same core number, and also has the blind insertion function, which is convenient and quick to use. This series of connectors features fast insertion, high density, waterproof, small size, blind insertion and high life. It is especially suitable for high-density installations, relatively small space installations, and places where it is difficult to separate by rotation. Can be applied to harsh environments in the field, protection class IP68.Connector assures a reliable connection with corresponding Fischers connector and connector of other companies of the same type making it. Making it an ideal choice for Medical, Test & Measurement, Research, Communications, Broadcast Connector, Machines, Defense, Robotic, Aerospace, public sector, Information Systems, Motorsport, Miscellaneous applications. These high quality Spring Technology connectors cable assembly can be provided. it can cross Fischer variations and sizes.

2. F series connector description:

- security of the Push-Pull self-latching system

- multipole types 2 to 40 contacts

- Easy mating, can be blind-mated (guiding mechanism ensures precise alignment)

- Increased equipment life span (guiding mechanism optimally protects the contacts)

- Robust and shock resistant (designs ideal for equipment used in the field)

- watertight connection (IP 68/IP 66),waterproof and sandproof;

- solder, print (straight or elbow) contacts

- high packing density for space savings

- 360°screening for full EMC shielding.

3. F series connector technical specification:

| Mating Cycles | Humidity(max) | Temperature | Vibration | Shock Resistance | Salt Spray Corrosion | Impact |

| >3000 | <=95% (at 40℃) | -55℃ ~ +145℃ | 15g(10 ~ 2000 Hz) | 100g·6ms | >48h | acceleration 490m/s², ≤1um instantaneous break |

4. Cross reference

Plug

| Spring P/N | TG Straight long plug | TG Straight plug (with bend relief) |

TY Straight short plug | TL Straight short plug | TW Elbow(90°) plug |

| Fischer P/N | S Straight long plug | S Straight plug (with bend relief) |

SS Straight short plug | SS Straight short plug | WSO Elbow(90°) plug |

| Picture |  |

|

|

|

|

| Shell Size | 102F/103F/1031F/104F/105F | 102F/103F/1031F/104F/105F | 102F/103F/1031F/104F/105F | 102F/103F/1031F/104F/105F | 102F/103F/1031F/104F/105F |

| NB of Contacts | 2~40 | 2~40 | 2~40 | 2~40 | 2~40 |

| Keying | N, A, B | N, A, B | N, A, B | N, A, B | N, A, B |

| Insulator | PPS/PEEK | PPS/PEEK | PPS/PEEK | PPS/PEEK | PPS/PEEK |

| Contact Type | Solder Male contact |

Solder Male contact |

Solder Male contact |

Solder Male contact |

Solder Male contact |

| IP Level | IP68 | IP68 | IP68 | IP68 | IP68 |

| Wire Size/AWG | 10~28 | 10~28 | 10~28 | 10~28 | 10~28 |

| Cable Diameter(mm) | 1.5~11.5 | 1.5~11.5 | 1.5~11.5 | 1.5~11.5 | 1.5~11.5 |

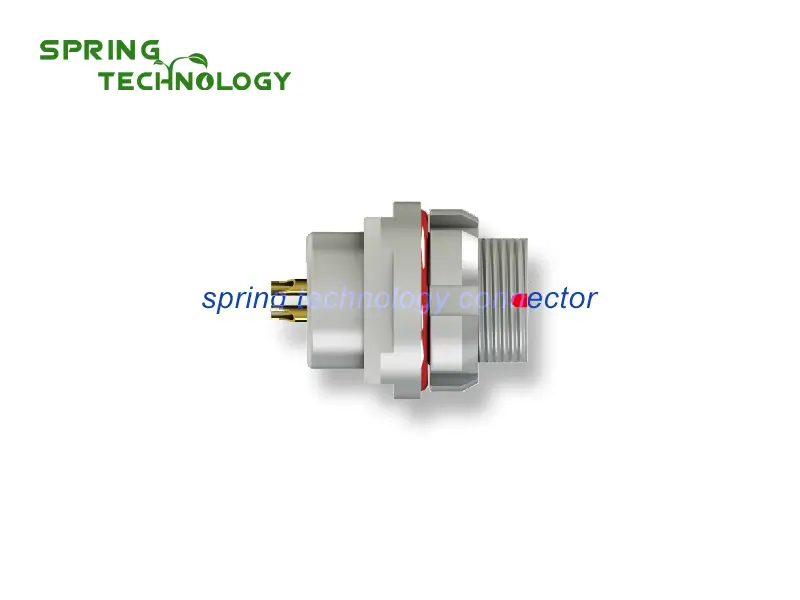

Hermetic Socket

| Spring P/N | ZL Hermetic Socket | ZL Hermetic Socket (elbow(90°) contacts) |

G8 Hermetic Socket | ZG Hermetic Socket | ZY Hermetic Short Socket | ZH Hermetic Socket (Front Projecting) |

MH Hermetic Socket (Front Projecting) |

| Fischer P/N | DBPU Hermetic Socket | DBPC Socket (elbow(90°) contacts) |

D Hermetic Socket | DG Hermetic Short Socket | DBEU Hermetic Socket (Front Projecting) |

DBPLU Hermetic Socket (Front Projecting) |

|

| Picture |  |

|

|

|

|

|

|

| Shell Size | 102F/103F/1031F /104F/105F |

102F/103F/1031F /104F/105F |

102F/103F/1031F /104F/105F |

102F/103F | 102F/103F | 102F/103F | 102F/103F |

| NB of Contacts | 2~40 | 2~40 | 2~40 | 2~16 | 2~16 | 2~16 | 2~16 |

| Keying | N, A, B | N, A, B | N, A, B | N, A, B | N, A, B | N, A, B | N, A, B |

| Insulator | PPS/PEEK | PPS/PEEK | PPS/PEEK | PPS/PEEK | PPS/PEEK | PPS/PEEK | PPS/PEEK |

| Contact Type | Solder/Print Female contact |

Elbow Print Female contact |

Solder Female contact |

Solder Female contact |

Solder Female contact |

Solder Female contact |

Solder Female contact |

| IP Level | IP68 | IP68 | IP68 | IP68 | IP68 | IP68 | IP68 |

| Wire Size/AWG | 10~28 | 10~28 | 10~28 | 20~28 | 20~28 | 20~28 | 20~28 |

| Panel Size | M9/M14/16/M20 | M9/M14/16/M20 | M9/M14/16/M20 | M9/M14 | M9/M14 | M9/M14 | M10/M14 |

| Panel Mounted | Back | Back | Back | Back | Back | Front | Back |

Free Socket and Other Socket

| Spring P/N | DH Free Socket | DF Free Socket | MF Socket (Front Projecting Flange Square Corner Screw) |

| Fischer P/N | KE Free Socket | DK Free Socket | |

| Picture |  |

|

|

| Shell Size | 102F/103F/1031F /104F/105F |

102F/103F | 103F/1031F/105F |

| NB of Contacts | 2~40 | 2~16 | 2~40 |

| Keying | N, A, B | N, A, B | N, A, B |

| Insulator | PPS/PEEK | PPS/PEEK | PPS/PEEK |

| Contact Type | Solder Female contact |

Solder Female contact |

Solder Female contact |

| IP Level | IP68 | IP68 | IP68 |

| Wire Size/AWG | 10~28 | 20~28 | 10~28 |

| Cable Diameter(mm) | 1.5~11.5 | 3.2~8.1 | – |

5. Chooseing tips:

If you have purchased fischer connector and know the original model, please tell us. We will directly offer you our corresponding one.

If you don’t know much about the connector, please make choose according the following factors:

- the use of the environment, indoors or outdoors, waterproof or not;

- the panel hole size, to select the appropriate plug and socket of right dimension;

- the current-voltage, number of contact and the realization of the function, to determine the contact(cores) ;

- select the appropriate clamp diameter and sheath;

- according to the actual needs of different angles of the keys, to determine the keying (the standard keys as N).

6, Why choose our

- Lower your cost, cheap cable assembly offer, at least save your 30%-50% cost (100% compatible and work well)

- large stock, short lead times. The delivery time is short, the parts are in stock. Just need to assemble them.

- better quality at a reasonable price

- We can provide OEM/ODM service and cable assembly solution.

- Our factory has 17 years experience and strong and professional research and development capabilities.Advanced development and management, comprehensive R&D testing and highly automatic production line make our products high reliability and high performance.